Thorough cleaning and disinfection

Conveyor belts are indispensable in many industries. They transport products, materials and waste in production, warehousing and logistics. To keep these conveyor belts clean, regular cleaning is necessary. Traditionally, cleaning conveyor belts is done with water or chemicals. However, these methods are often time-consuming and harmful to the environment. A new and efficient alternative to cleaning conveyor belts is steam cleaning. Dry steam is an ideal cleaning agent because it has a strong cleaning effect, but is also environmentally friendly and safe.

Dirty and contaminated conveyor belts are a thing of the past. Our conveyor belt cleaning systems clean reliably and thoroughly, without any chemicals. FRANK conveyor belt cleaning systems enable automated, simple and cost-effective cleaning of closed and open conveyor belts such as plastic modular belts, chain link belts, link belt conveyors and belt conveyors.

Our solutions

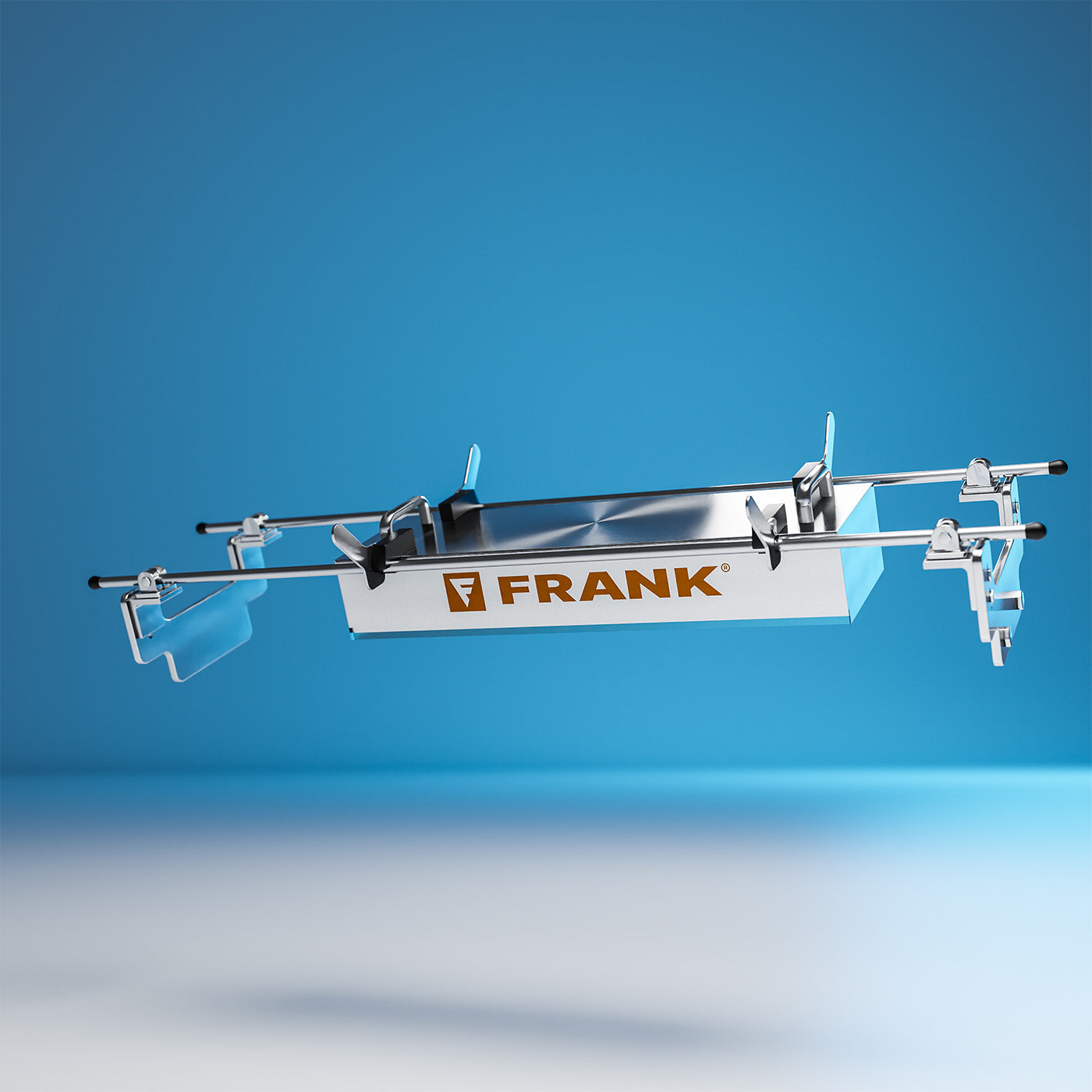

Belt Sanitation Unit

An automated cleaning system for closed conveyor belts that can be used during ongoing production. It uses hot steam to loosen the dirt and simultaneously vacuums it away, so that the belt is clean and thermally disinfected after just one pass. After the pass, the belt is almost immediately dry again and ready for further production steps.

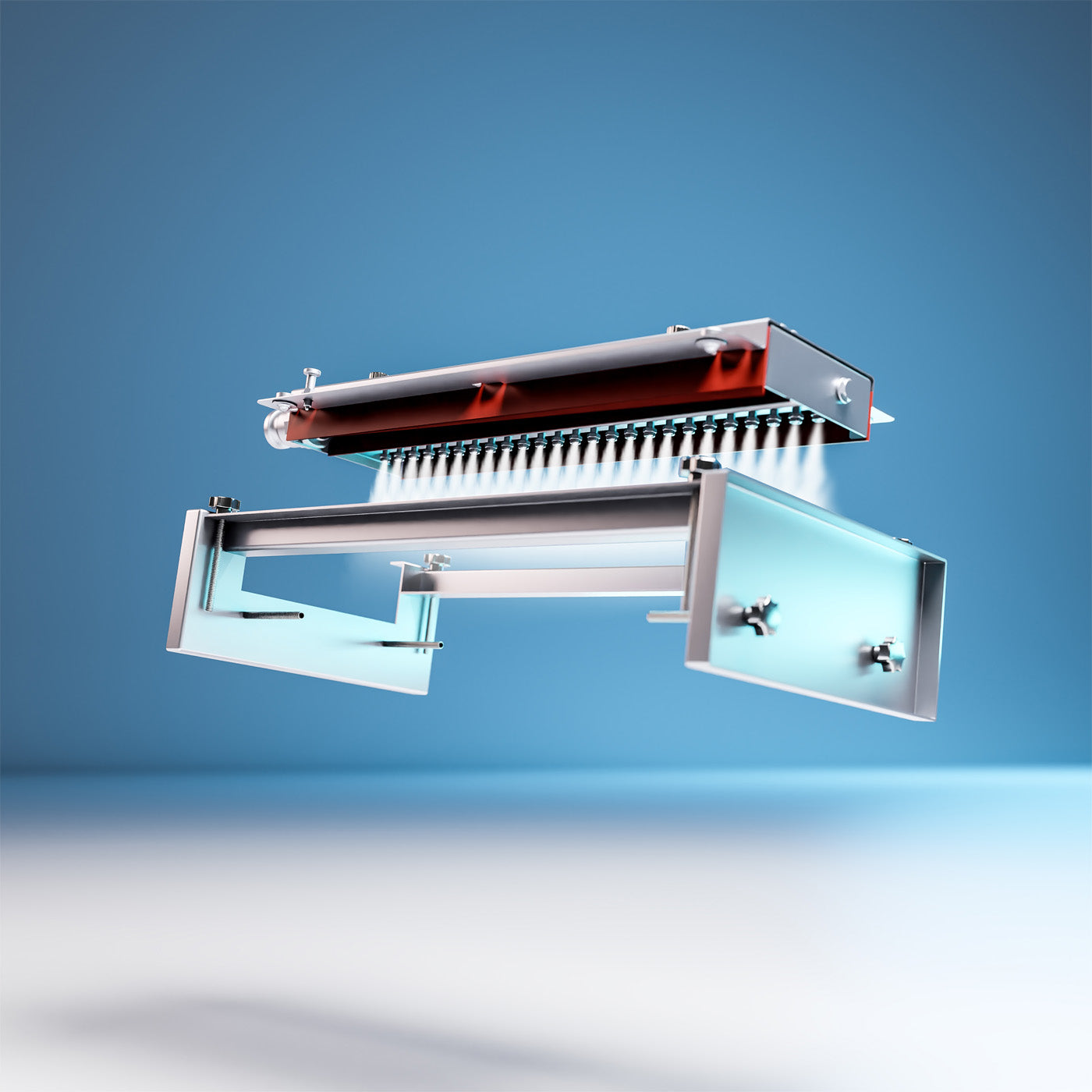

Belt Sanitation Unit Flex

A semi-automated cleaning system for closed conveyor belts that uses hot steam to remove contaminants, which are then immediately transported away. The device can be manually moved left and right on the belt, so that even partially contaminated or very wide belts can be cleaned. After cleaning, the belt is clean, disinfected and almost immediately dry and ready for use again.

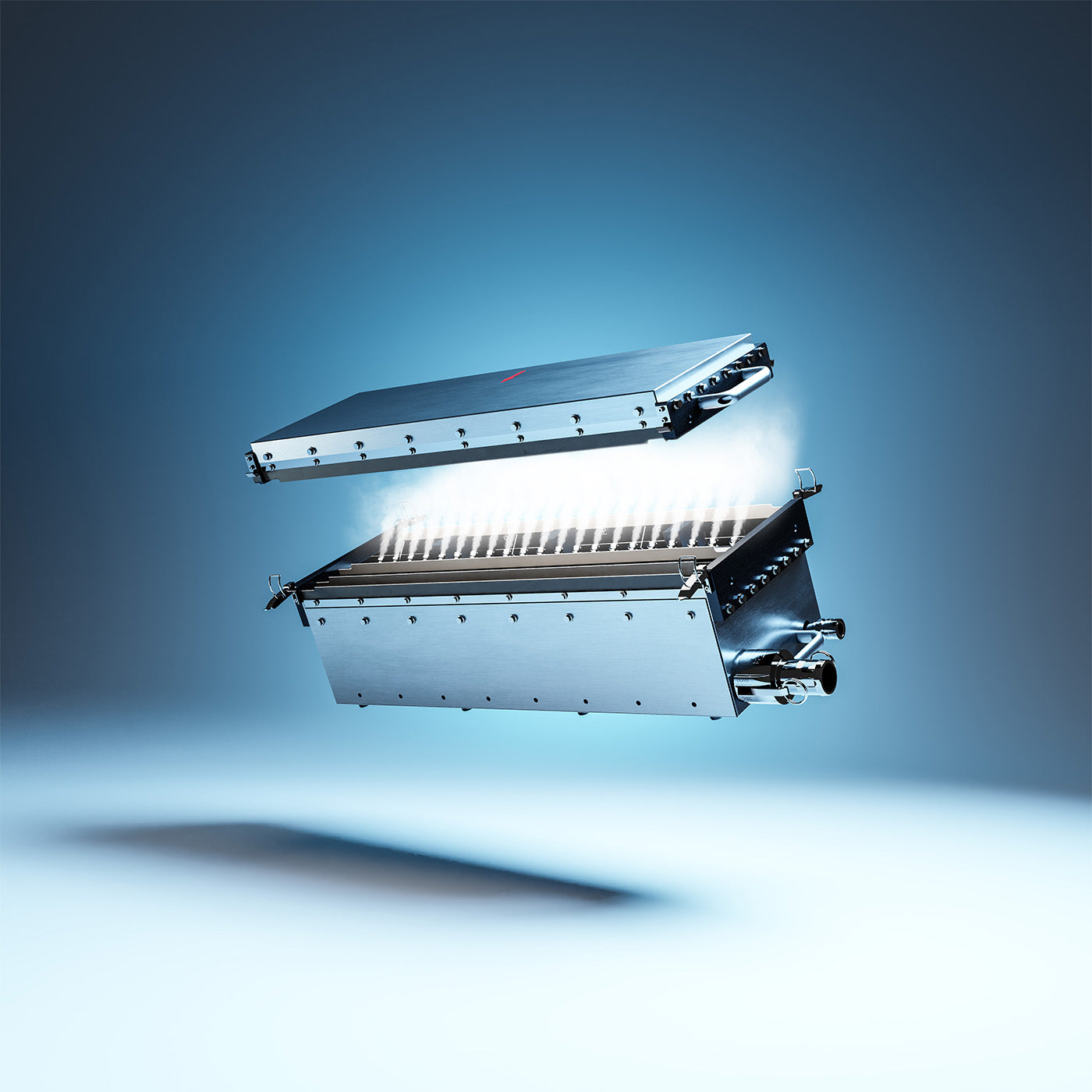

Cleanbox

An automated cleaning system for open conveyor belts that can be used during production and encloses the belt from above and below. Dirt is loosened from both sides using hot steam and then vacuumed away, so that the belt is clean, disinfected and almost immediately dry again after just one pass. Ready for the next production steps!

Individual belt cleaning solutions

Our belt cleaning systems are ideally tailored to your application so that you get the best possible result. We proceed as follows:

Request for quotation

You send us a request for a quote for your desired belt cleaning solution.

Initial conversation

In an initial discussion, we will determine what your requirements are and which solution is best for you.

On-site data collection

In order to be able to offer you the perfect solution, we come to the desired location and record all relevant data about the conveyor belt.

Individual offer

You will receive an individual offer from us that is tailored exactly to your application.

installation

Once the order has been placed, we install all components of the belt cleaning system at the desired location.

Advantages of conveyor belt cleaning with dry steam from FRANK

Conveyor belt cleaning with dry steam: The efficient and sustainable solution

Efficient

Dry steam from FRANK removes even stubborn dirt such as grease, oil, adhesives and food residue quickly and thoroughly.

Environmentally friendly

Dry steam is a sustainable cleaning agent because it does not require chemicals or water.

Secure

Dry steam from FRANK is harmless to people and machines.

Reduces downtime

Conveyor belts can be cleaned quickly and easily with dry steam from FRANK without having to interrupt production or operations.

Areas of application

Food industry

Dry steam from FRANK is ideal for cleaning conveyor belts in food processing. It safely and hygienically removes grease, oil, protein and other food residues.

logistics

Dry steam from FRANK is an efficient solution for cleaning conveyor belts in warehouses and logistics. It removes dust, dirt and contamination caused by the transport of goods.

production

Dry steam from FRANK is an effective cleaning agent for conveyor belts in production. It removes production residues such as grease, oil, dirt and dust.

Chemical industry

FRANK dry steam is a safe and efficient solution for cleaning conveyor belts in the chemical industry. It removes hazardous chemicals and residues without harming the environment.

How do our belt cleaning systems work?

Our belt cleaning systems always consist of several components that are perfectly tailored to the conveyor belt to be cleaned. Depending on the type and width of the belt, a different belt cleaner, more steam power or a more powerful vacuum cleaner is required. However, the basic structure of our belt cleaning systems with dry steam cleaner, belt cleaner and vacuum cleaner always remains the same.

The principle

Belt cleaner

Our unique conveyor belt cleaners are perfectly adapted to different types of belt and form a cleaning chamber directly on the belt. Here the dry steam can develop its full effect and dirt can be effectively removed.

Industrial vacuum cleaner

The loosened dirt is removed quickly and reliably by our industrial vacuum cleaners. Thanks to the combination of vacuum cleaner and dry steam, the belt is almost immediately dry after the cleaning process.

Belt cleaner

Our unique conveyor belt cleaners are perfectly adapted to different types of belt and form a cleaning chamber directly on the belt. Here the dry steam can develop its full effect and dirt can be effectively removed.

Industrial vacuum cleaner

The loosened dirt is removed quickly and reliably by our industrial vacuum cleaners. Thanks to the combination of vacuum cleaner and dry steam, the belt is almost immediately dry after the cleaning process.