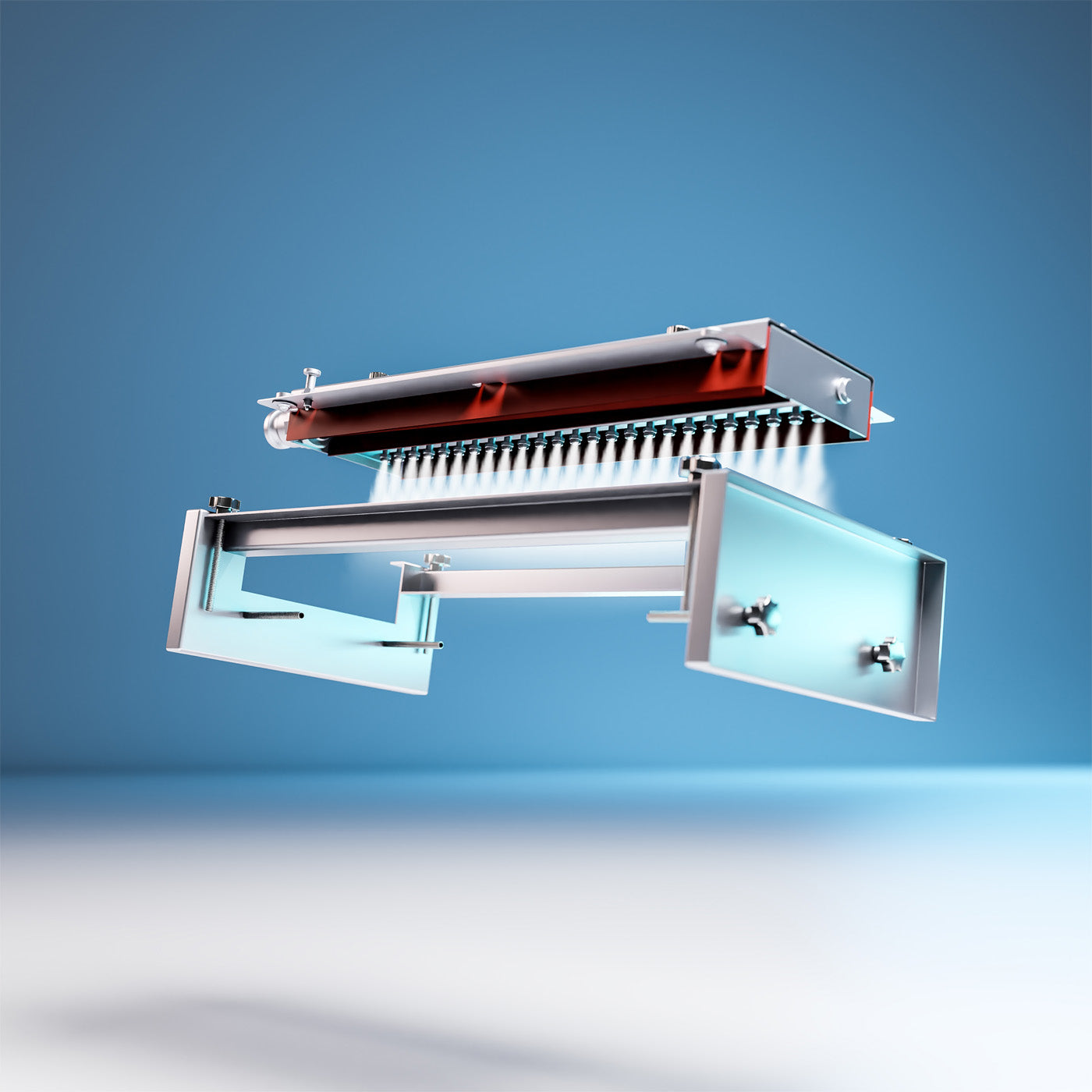

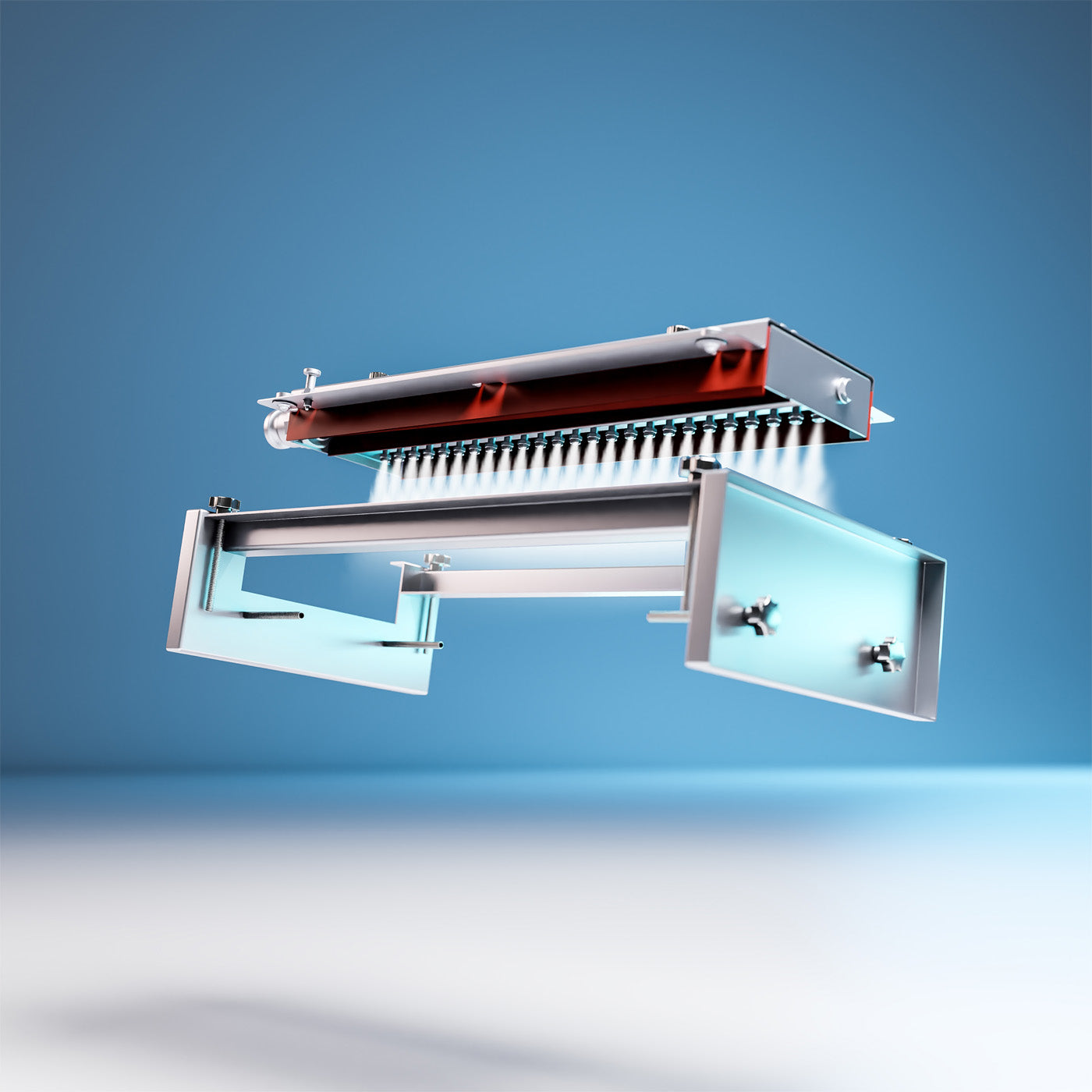

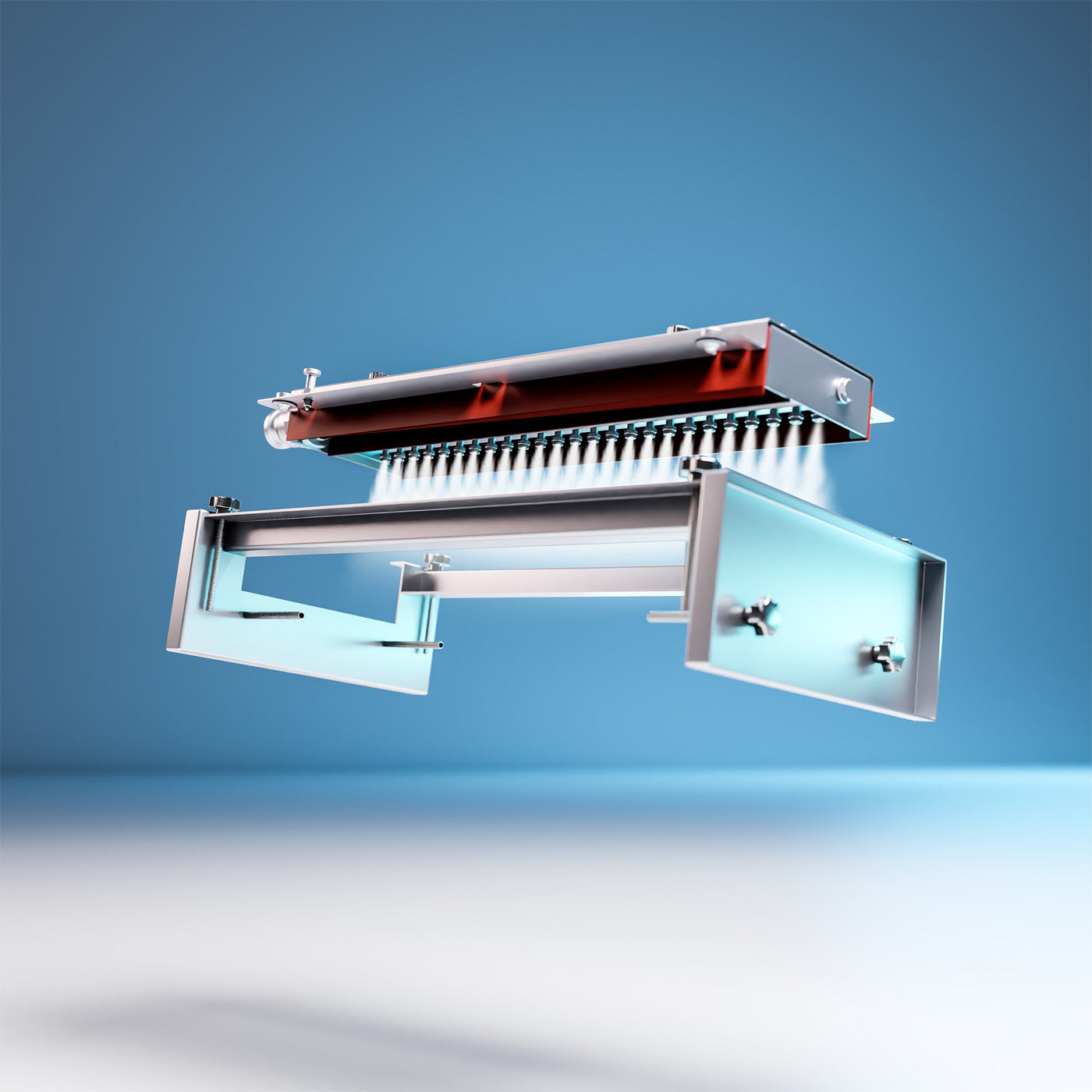

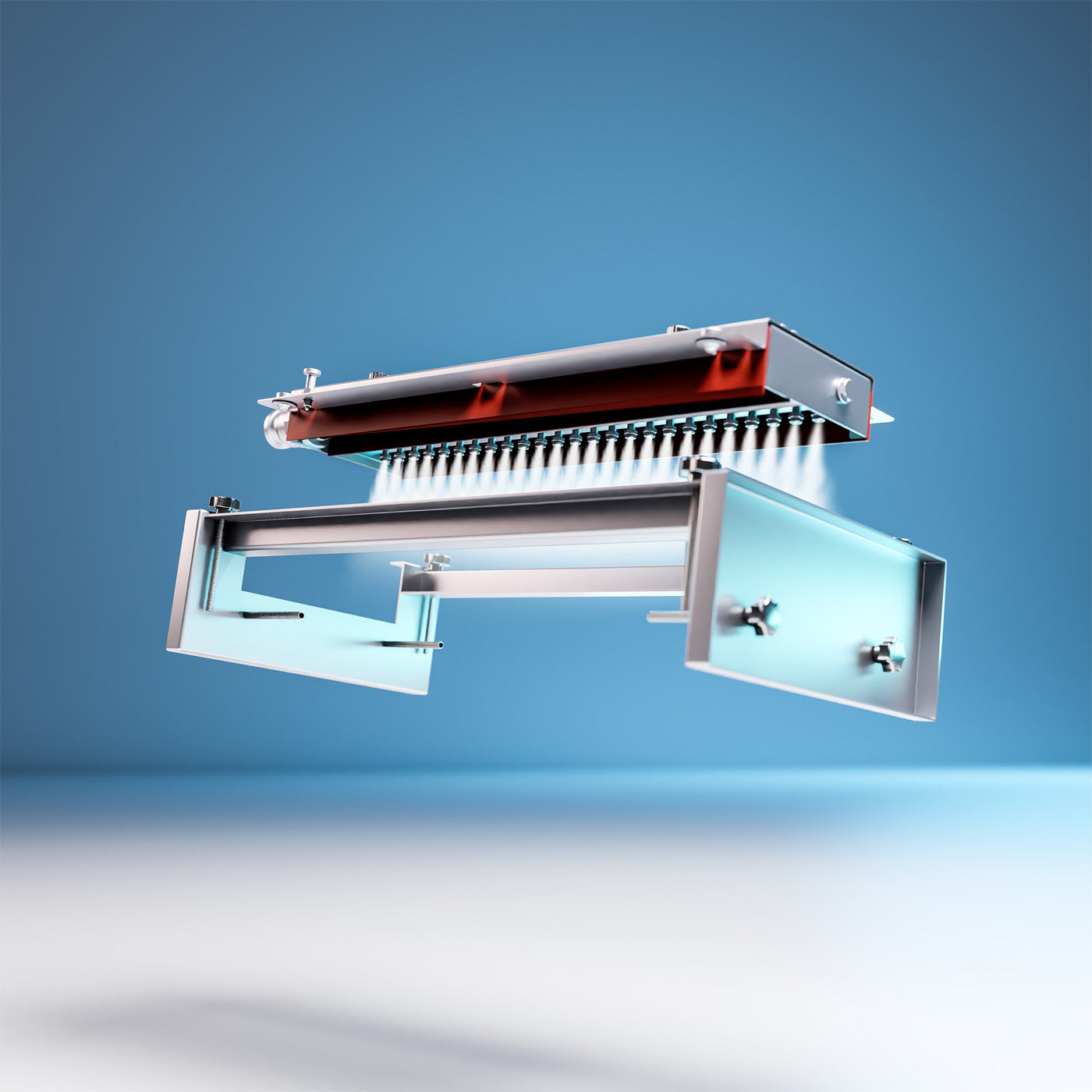

Belt Sanitation Unit

Conveyor belt cleaner

The Belt Sanitation Unit (BSU) is part of an automated system for cleaning closed conveyor belts. The hot steam not only removes dirt, but also thermally disinfects the belt at the same time, removing bacteria, viruses and allergens. Once installed, the belt can be cleaned continuously during ongoing production and is then almost immediately dry and ready for further production steps. By eliminating cleaning shifts, time is saved and since no manual intervention is required during cleaning, staff have the opportunity to concentrate on more important tasks.

Choose options

How do our belt cleaning systems work?

Our belt cleaning systems always consist of several components that are perfectly tailored to the conveyor belt to be cleaned. Depending on the type and width of the belt, a different belt cleaner, more steam power or a more powerful vacuum cleaner is required. However, the basic structure of our belt cleaning systems with dry steam cleaner, belt cleaner and vacuum cleaner always remains the same.

The components

Belt cleaner

Our unique conveyor belt cleaners are perfectly adapted to different types of belt and form a cleaning chamber directly on the belt. Here the dry steam can develop its full effect and dirt can be effectively removed.

Industrial vacuum cleaner

The loosened dirt is removed quickly and reliably by our industrial vacuum cleaners. Thanks to the combination of vacuum cleaner and dry steam, the belt is almost immediately dry after the cleaning process.

Belt cleaner

Our unique conveyor belt cleaners are perfectly adapted to different types of belt and form a cleaning chamber directly on the belt. Here the dry steam can develop its full effect and dirt can be effectively removed.

Industrial vacuum cleaner

The loosened dirt is removed quickly and reliably by our industrial vacuum cleaners. Thanks to the combination of vacuum cleaner and dry steam, the belt is almost immediately dry after the cleaning process.

How much power do I need?

Depending on the width of the belt, more or less steam power is required to clean the conveyor belt efficiently and thoroughly. Although the right choice of power depends on other factors such as the condition of the belt, we generally recommend the following dry steam cleaners:

up to 400mm

For very narrow belts we recommend using our dry steam cleaner mS 10 .

up to 600mm

For smaller belts up to 600 mm, the dry steam cleaner iS 18 should be used.

up to 800mm

For a belt width between 600 and 800 mm, our dry steam cleaner iS 36 should be used for optimal results.