Challenges and solutions

In industrial production, conveyor belts are essential for the efficient transport of materials and products. However, they are also susceptible to dirt and contamination, which requires regular and thorough cleaning. In the food industry in particular, cleanliness is crucial to comply with hygiene regulations and ensure product quality.

The challenges of conveyor belt cleaning

Conveyor belts run continuously and are often difficult to access, making them difficult to clean. Production residues, oils and greases can contaminate the surface of the belts, which not only affects production efficiency but also poses the risk of cross-contamination. Traditional cleaning solutions are often resource-intensive and require large amounts of water and chemicals, which is both costly and environmentally disadvantageous.

Sustainable and efficient cleaning techniques

In recent years, several innovative cleaning techniques have been developed to address these challenges. Efficient mechanical brush and scraper systems as well as dry ice blasting offer sustainable alternatives to traditional methods. These techniques minimize water consumption and often do not require harsh chemicals, making them more environmentally friendly.

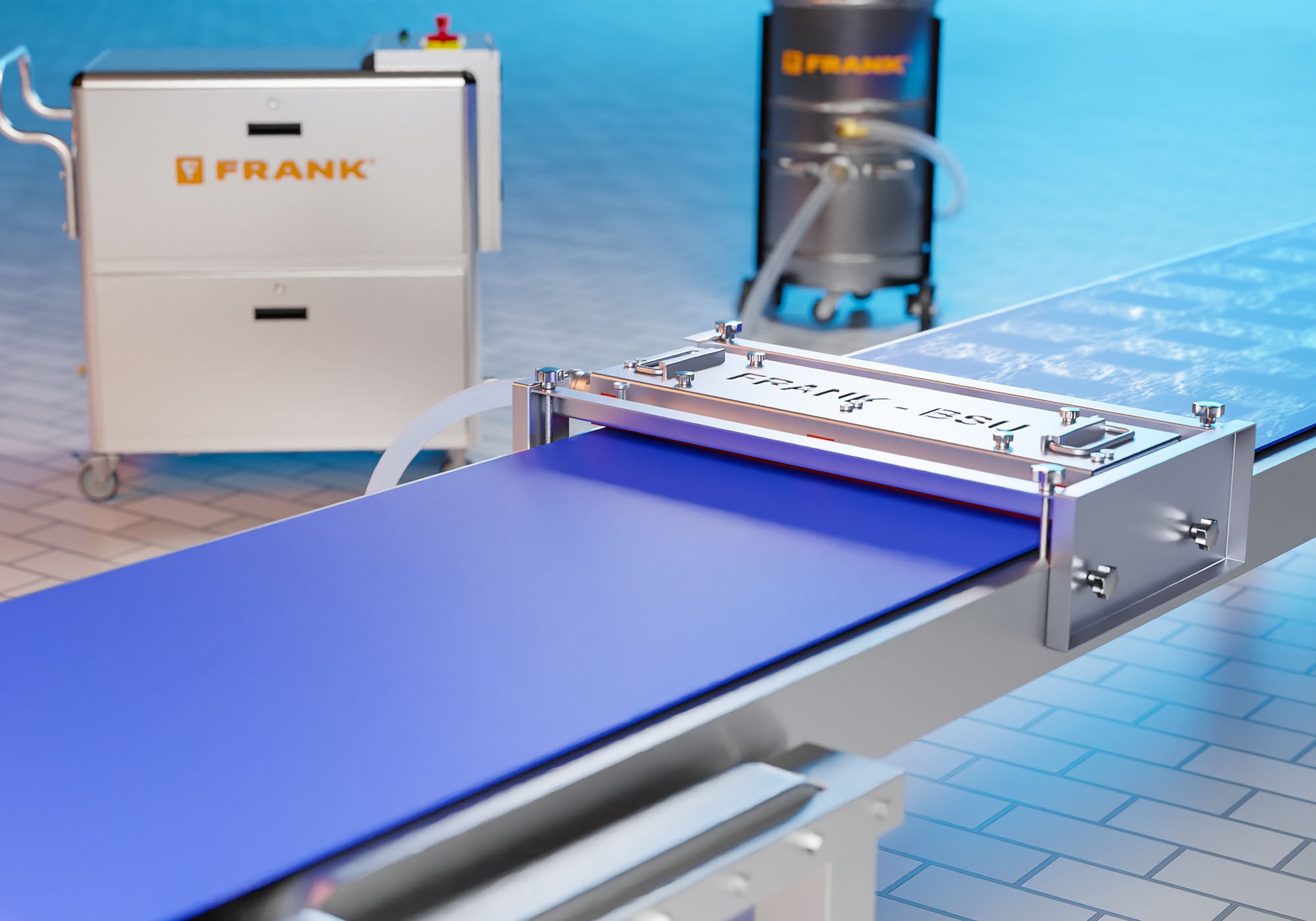

The solution: FRANK BSU belt cleaner

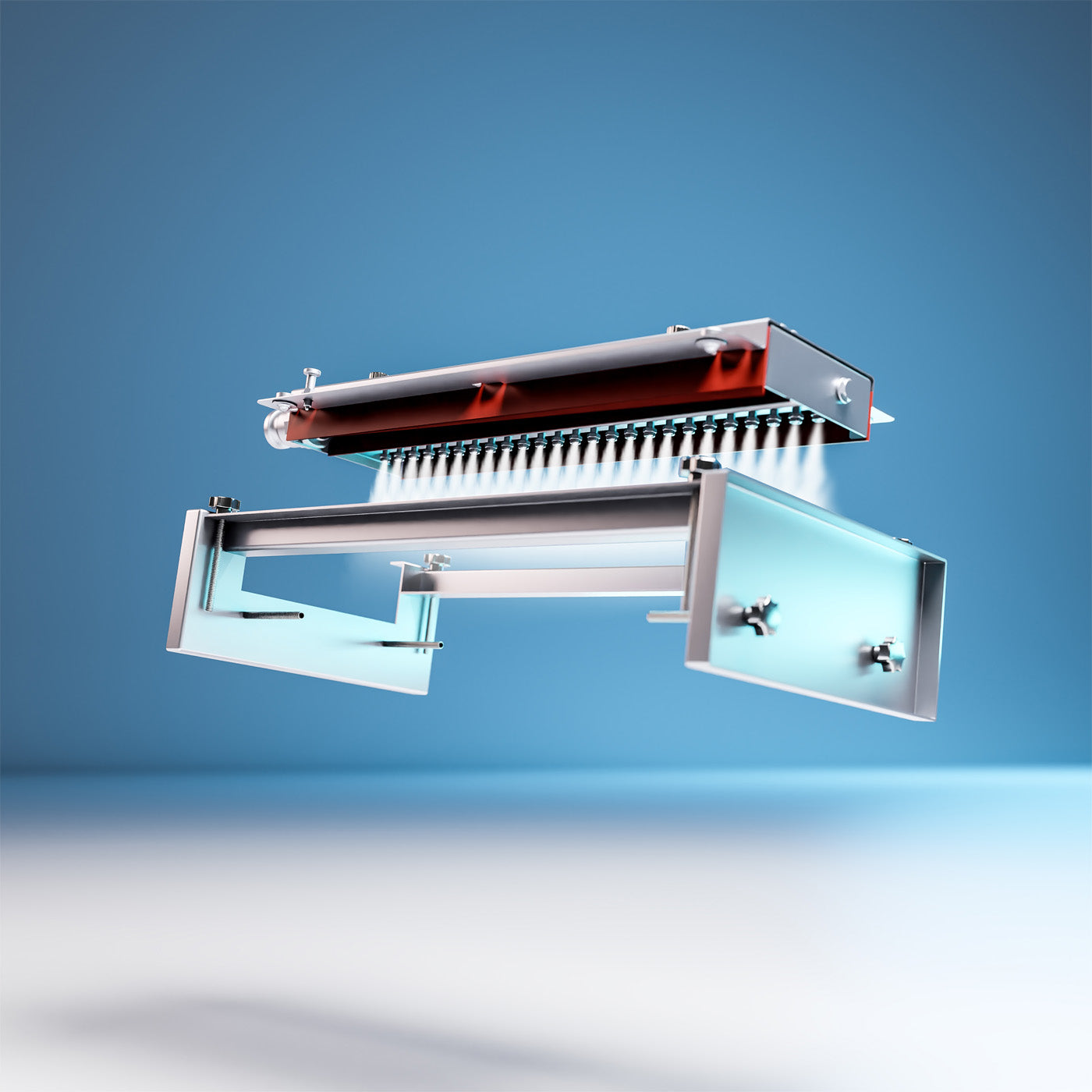

An outstanding example of an efficient and sustainable cleaning solution is the BSU belt cleaner from FRANK Hochdruck- & Dampftechnologie GmbH. This belt cleaner was specially developed to remove dirt and production residues quickly and effectively, even during ongoing production. The BSU belt cleaner uses minimal water and does not require any chemical cleaning agents, which makes it particularly environmentally friendly.

The BSU belt cleaner from FRANK has several key advantages over the other methods. While mechanical brush systems can wear out the conveyor belts, the BSU cleans thoroughly without mechanical impact, which extends the life of the belts. In addition, the BSU completely removes both coarse and fine contamination, which dry ice blasting often cannot achieve. Another advantage is the possibility of continuous operation. The BSU can be used during production operations, thus avoiding downtime. This is a clear advantage over many other methods that require interruption of production.

Another notable aspect is the chemical-free disinfection. The BSU achieves high hygiene performance without the use of chemicals, which is both environmentally friendly and increases the safety of the production environment. In addition, the BSU's water consumption is extremely low, making it a sustainable solution that allows significant savings compared to traditional methods.

Conclusion

Cleaning conveyor belts is a complex task that requires innovative and sustainable solutions. While mechanical brush and scraper systems and dry ice blasting each offer their own advantages, the BSU belt cleaner from FRANK Hochdruck- & Dampftechnologie GmbH represents a superior solution. It combines efficiency, sustainability and user-friendliness and meets the industry's high demands for cleanliness and hygiene. This technology enables companies to maximize their production capacities while maintaining high hygiene standards.