-

Make an enquiry nowARE YOU INTERESTED IN

OUR PRODUCTS?Let us advise you without obligation

-

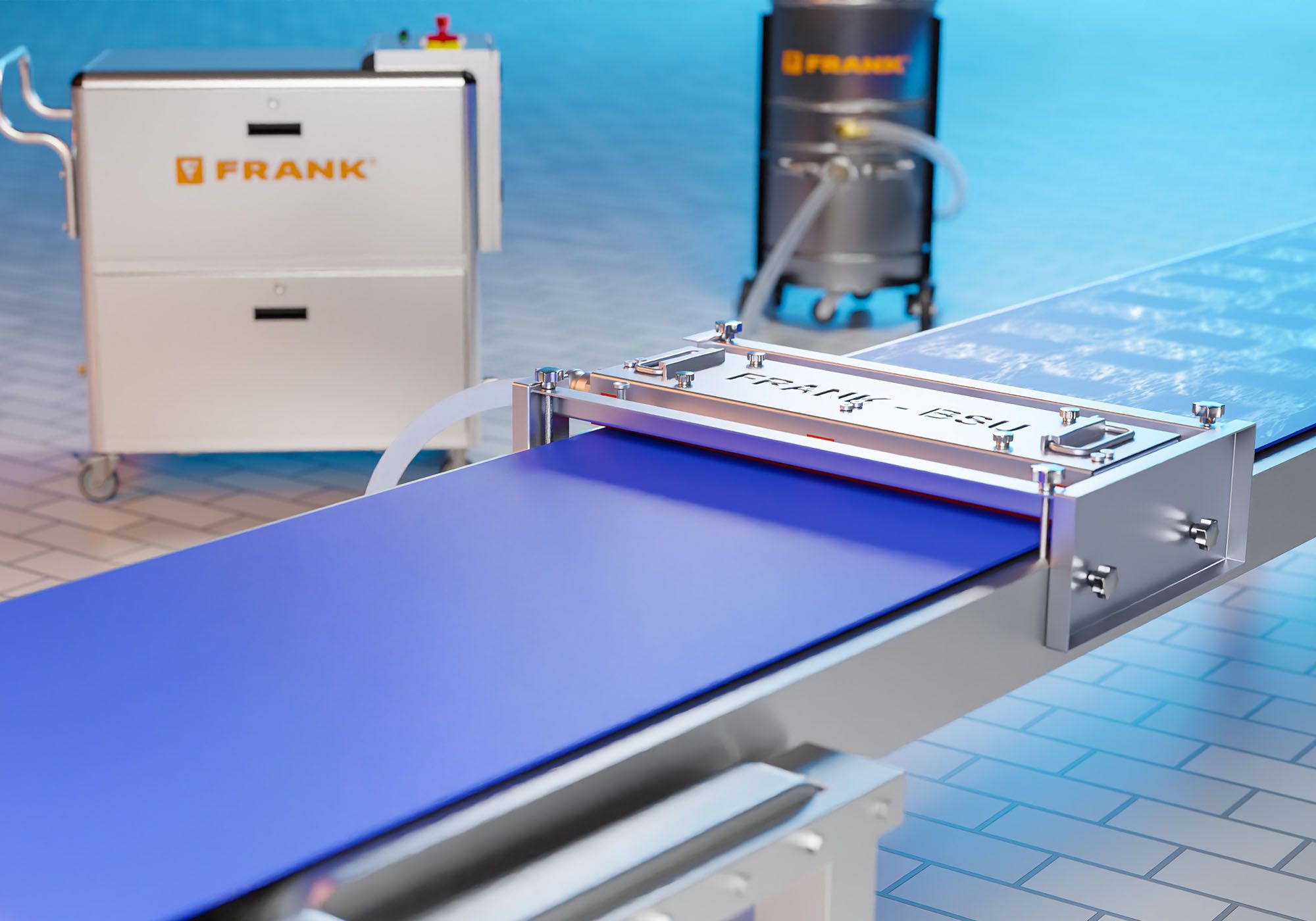

Belt cleaner BSU

Fast cleaning, even during ongoing production

back to overviewThe BSU belt cleaner is used to remove dirt and production residues and makes the surface ready for subsequent processes. The FRANK conveyor belt cleaning system achieves a Log 3-4 reduction, measured with an ATP luminometer, without any chemicals. It cleans and disinfects in one step.

-